Worldwide Delivery

With sites in 5 languages, we ship to

over 200 countries & regions.

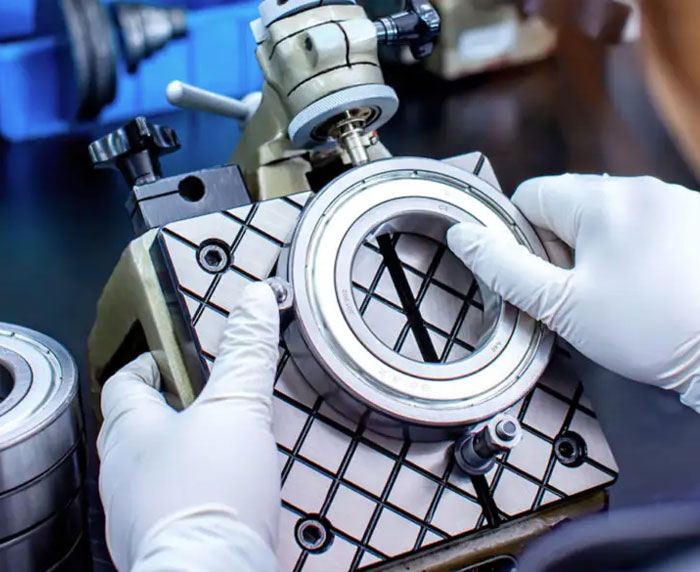

NR Bearing (Shandong) Co., Ltd. was established in 2001. It is a company specializing in the production, design, R&D and testing of high-quality bearings. The company has more than 20 years of experience in bearing manufacturing and use, and has advanced technology R&D, inspection and testing capabilities. Our product range mainly includes ball bearings, roller bearings and unit bearings. We produce more than 60,000 types of bearings, ranging from 1.5mm I.D. to 4000mm outer diameter, with an annual output of 50 million sets. As a trusted bearing manufacturer, we are proud to provide high-quality products and excellent technical support tailored to your application needs.

Products are widely used in a variety of industrial fields such as automobiles and agricultural machinery, high-precision CNC machinery, ultra-high-speed electric spindle devices, wind energy, solar energy equipment, etc. NR has established its own technical center and professional bearing engineering technology research and development center, dedicated to the development of new products and the enhancement of bearing design functions.

The company has three major experimental centers for material analysis, physical and chemical experiments, and precision measurement. NR bearings use online detection and SPC process control systems to achieve full monitoring and tracking of the product process. Our core technology and key products ensure its leading position in the international market. NR is committed to providing customers with the best and most perfect bearing solutions. NR Bearing Company has gradually become one of the comprehensive manufacturers in China's bearing industry integrating production, testing, sales, warehousing and distribution.

When designing the bearing scheme, the customer needs must be analyzed in depth.

For example, in the wind power equipment, the yaw pitch bearing and the main bearing shall be able to withstand the complex working conditions, and the strong wind impact, sharp temperature fluctuation and other factors shall be considered

Product Design

Engineer

In the production process, there may be many process problems!

Optimize the steel production process, adjust the processing parameters of rollers, calibrate the processing equipment, and strive to ensure the dimensional accuracy of the produced rollers meets the standard, which is the process of continuously solving process problems and guaranteeing product quality.

Materials R&D

Engineer

Technical support!

Recommending suitable precision bearings for users is the basic principle for good customer service!

Technical support

Engineer

With sites in 5 languages, we ship to

over 200 countries & regions.

Recommend suitable precision bearings for users .

Round-the-clock assistance for a smooth

shopping experience.