Description

| Bore type | Tapered 1:12 |

Dimensions

| d | 85 mm | Bore diameter |

|---|---|---|

| tΔdmp | 0.0 – 0.035 mm | Deviation limits of mid-range bore diameter |

| tΔSL | 0.0 – 0.035 mm | Deviation limits of tapered slope |

| D | 180 mm | Outside diameter |

| tΔDmp | -0.025 – 0.0 mm | Deviation limits of mid-range outside diameter |

| B | 69 mm | Width |

| tΔBs | -0.08 – 0.0 mm | Deviation limits of ring width |

| d2 | ≈ 103 mm | Shoulder diameter of inner ring |

| D1 | ≈ 158 mm | Shoulder/recess diameter of outer ring |

| b | 8.3 mm | Width of lubrication groove |

| K | 4.5 mm | Diameter of lubrication hole |

| r1,2 | min. 3 mm | Chamfer dimension |

| Normal | ISO tolerance class for dimensions |

Abutment dimensions

| Da | max. 166 mm | Diameter of housing abutment |

|---|---|---|

| ra | max. 2.5 mm | Radius of fillet |

Calculation data

| NR performance class | NR Explorer | |

| Basic dynamic load rating | C | 577 kN |

| Basic static load rating | C0 | 620 kN |

| Fatigue load limit | Pu | 61 kN |

| Limiting speed | 1 900 r/min | |

| Limiting value | e | 0.33 |

| Calculation factor | Y1 | 2 |

| Calculation factor | Y2 | 3 |

| Calculation factor | Y0 | 2 |

Tolerances of run-out

| Range of section height at inner ring of assembled bearing | tKia | 6 µm |

|---|---|---|

| Maximum run-out of inner ring side face to the bore | tSd | 9 µm |

| Range of section height at outer ring of assembled bearing | tKea | 13 µm |

| Perpendicularity of outer ring outside surface | tSD | 5 µm |

| ISO tolerance class for geoal tolerances | P5 |

Radial internal clearance

| Minimum initial clearance | 80 µm |

| Maximum initial clearance | 110 µm |

Mounting information

| Recommended tightening angle for lock nut | α | 150 ° |

|---|

Tolerances and clearances

General bearing specifications

- Tolerances: Normal, P6, P5,

tapered bore 1:12, tapered bore 1:30 - Radial internal clearance: cylindrical bore, tapered bore

Bearing interfaces

- Seat tolerances for standard conditions

- Tolerances and resultant fit

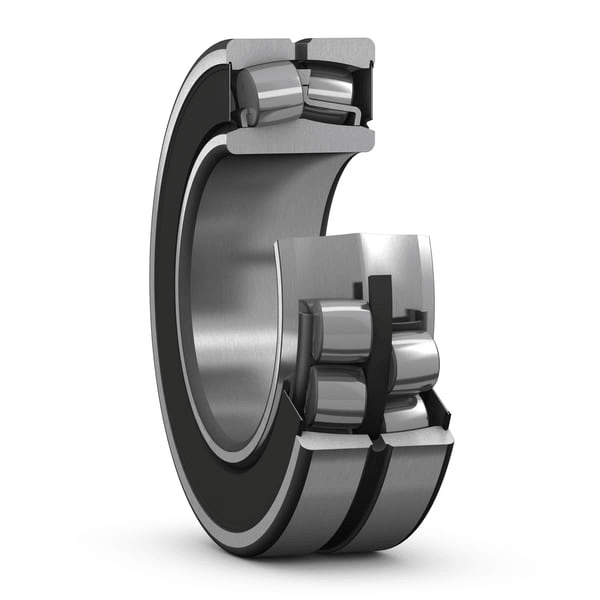

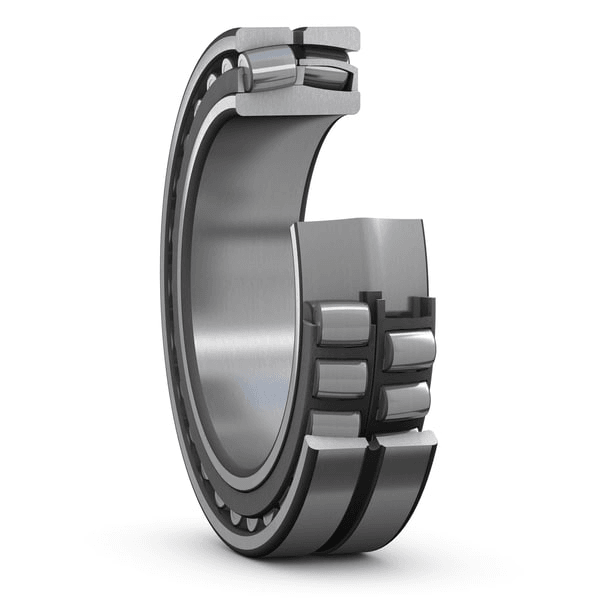

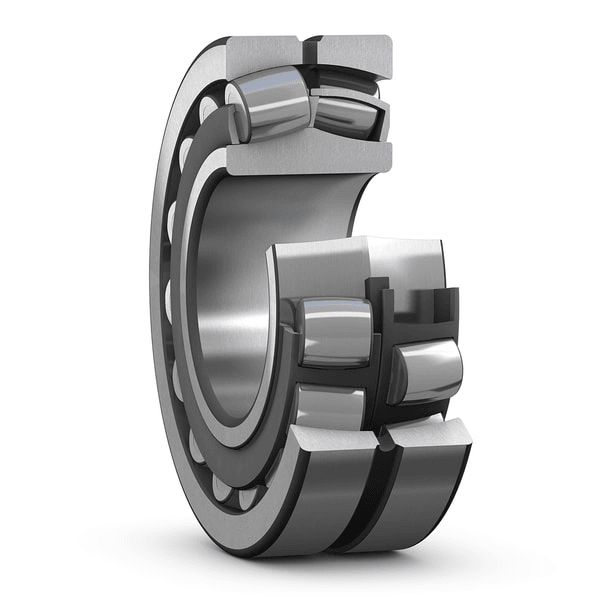

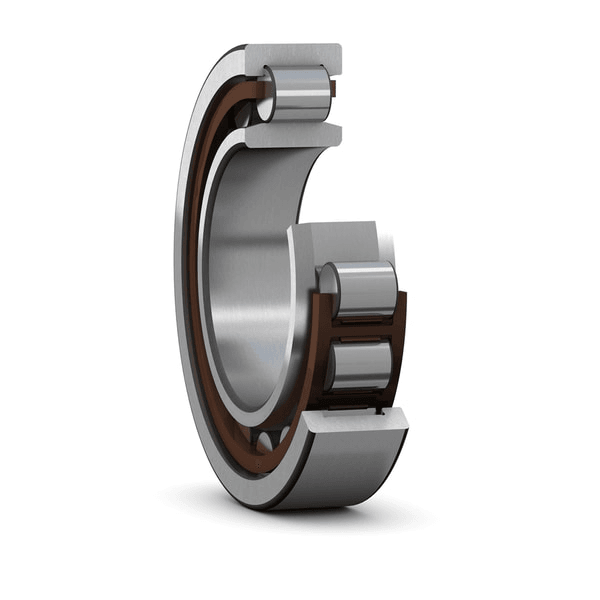

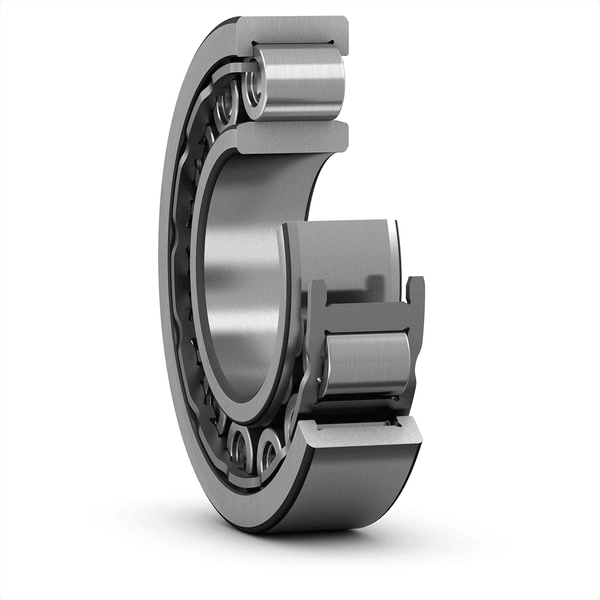

Spherical roller bearings can accommodate heavy loads in both directions. They are self-aligning and accommodate misalignment and shaft deflections, with virtually no increase in friction or temperature. Under normal operating conditions, sealed bearings are almost maintenance-free, keeping service costs and grease consumption low. The design includes features to facilitate relubrication.

- Accommodate misalignment

- High load carrying capacity

- Sealed for increased reliability, with relubrication features

- Low friction and long service life

- Increased wear resistance