Description

| Bore type | Cylindrical |

Dimensions

| d | 40 mm | Bore diameter |

|---|---|---|

| tΔdmp | -0.008 – 0.0 mm | Deviation limits of mid-range bore diameter |

| D | 90 mm | Outside diameter |

| tΔDmp | -0.013 – 0.0 mm | Deviation limits of mid-range outside diameter |

| B | 33 mm | Width |

| tΔBs | -0.06 – 0.0 mm | Deviation limits of ring width |

| d2 | ≈ 49.9 mm | Shoulder diameter of inner ring |

| D1 | ≈ 74.3 mm | Shoulder/recess diameter of outer ring |

| b | 6 mm | Width of lubrication groove |

| K | 3 mm | Diameter of lubrication hole |

| r1,2 | min. 1.5 mm | Chamfer dimension |

| Normal, bore to P5 and outside diameter P6 | ISO tolerance class for dimensions |

Abutment dimensions

| da | min. 49 mm | Diameter of shaft abutment |

|---|---|---|

| Da | max. 81 mm | Diameter of housing abutment |

| ra | max. 1.5 mm | Radius of fillet |

Calculation data

| NR performance class | NR Explorer | |

| Basic dynamic load rating | C | 155 kN |

| Basic static load rating | C0 | 140 kN |

| Fatigue load limit | Pu | 15 kN |

| Reference speed | 6 000 r/min | |

| Limiting speed | 8 000 r/min | |

| Limiting value | e | 0.37 |

| Calculation factor | Y1 | 1.8 |

| Calculation factor | Y2 | 2.7 |

| Calculation factor | Y0 | 1.8 |

| Permissible rotational acceleration for oil lubrication | 1 128 m/s² | |

| Permissible linear acceleration for oil lubrication | 304 m/s² |

Tolerances of run-out

| Range of section height at inner ring of assembled bearing | tKia | 5 µm |

|---|---|---|

| Maximum run-out of inner ring side face to the bore | tSd | 8 µm |

| Range of section height at outer ring of assembled bearing | tKea | 10 µm |

| Perpendicularity of outer ring outside surface | tSD | 4.5 µm |

| ISO tolerance class for geoal tolerances | P5 |

Radial internal clearance

| Minimum initial clearance | 60 µm |

| Maximum initial clearance | 80 µm |

Tolerances and clearances

General bearing specifications

- Tolerances: Normal, P6, P5,

tapered bore 1:12, tapered bore 1:30 - Radial internal clearance: cylindrical bore, tapered bore

Bearing interfaces

- Seat tolerances for standard conditions

- Tolerances and resultant fit

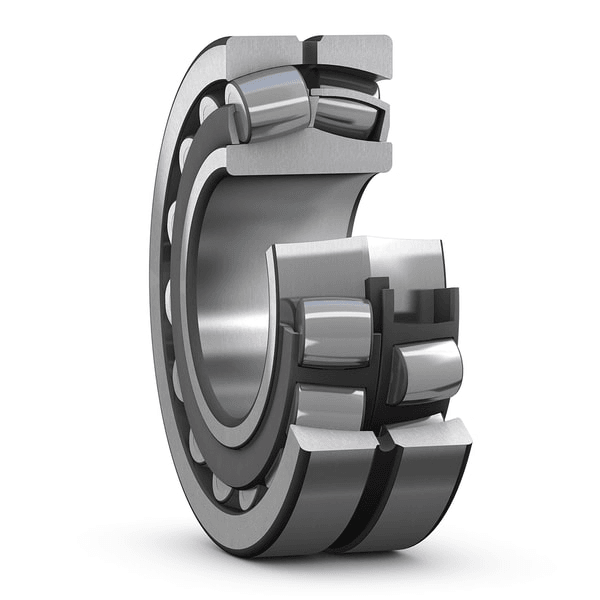

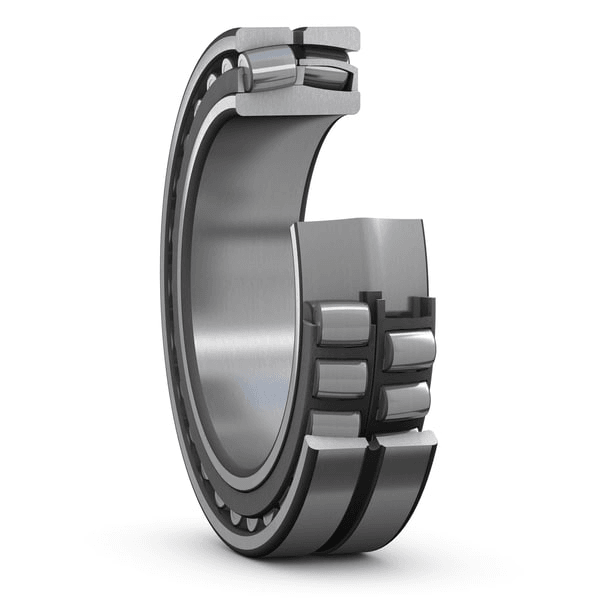

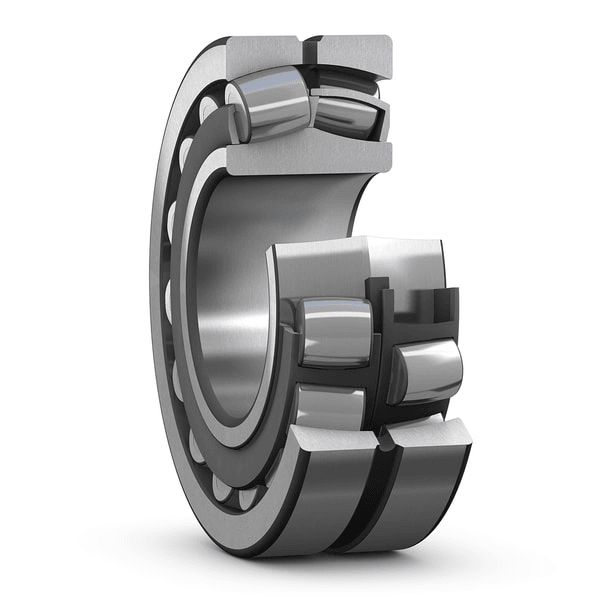

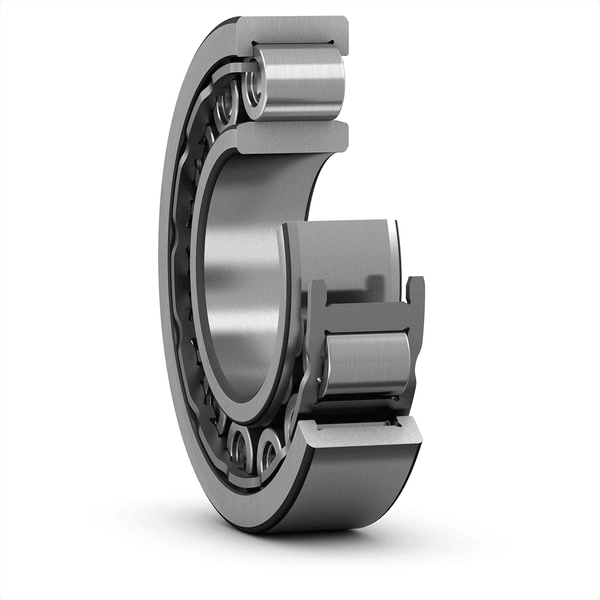

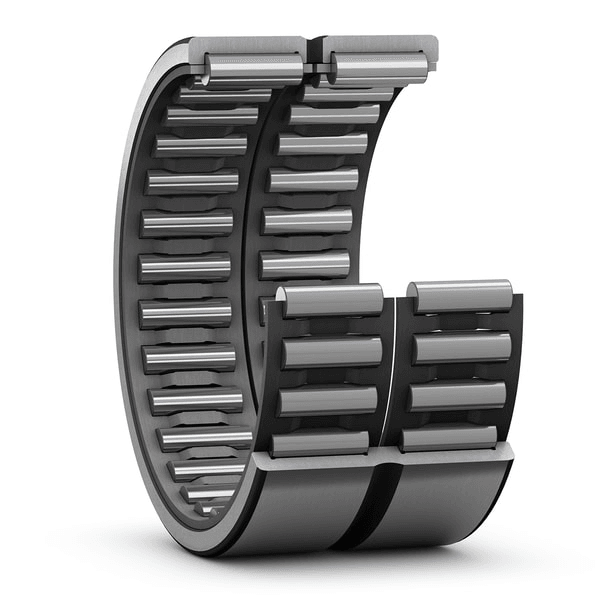

Spherical roller bearings can accommodate heavy loads in both directions. They are self-aligning and accommodate misalignment and shaft deflections, with virtually no increase in friction or temperature. This bearing design offers excellent performance in many types of vibrating machinery. The design includes features to facilitate relubrication. The bearings can be used in a modular system, including housings, sleeves and nuts.

- Accommodate misalignment

- High load carrying capacity

- Accommodate very high vibration levels

- Low friction and long service life

- Increased wear resistance