Description

Dimensions

| d | 75 mm | Bore diameter |

|---|---|---|

| D | 130 mm | Outside diameter |

| T | 80 mm | Total width |

| d1 | ≈ 100.65 mm | Shoulder diameter of inner ring |

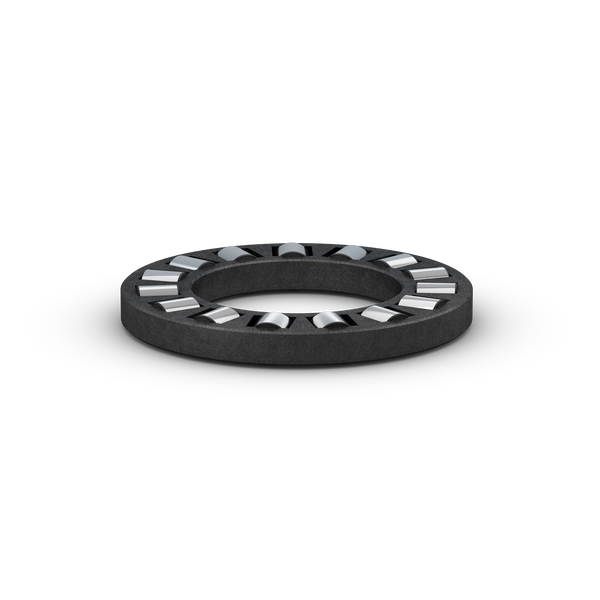

| l | 13.5 mm | Width of spacer ring |

| b | 8 mm | Width of lubrication groove |

| K | 5 mm | Diameter of lubrication hole |

| r1,2 | min. 2 mm | Chamfer dimension |

| r5 | min. 0.6 mm | Chamfer dimension |

| a | 72.029 mm | Distance between pressure points |

Abutment dimensions

| db | min. 85.5 mm | Diameter of shaft abutment |

|---|---|---|

| Db | min. 125 mm | Diameter of housing abutment |

| Cb | min. 6 mm | Minimum width of space required in housing on small side face |

| ra | max. 2 mm | Radius of fillet |

| rc | max. 0.6 mm | Radius of fillet |

Calculation data

| NR performance class | NR Explorer | |

| Basic dynamic load rating | C | 337 kN |

| Basic static load rating | C0 | 425 kN |

| Fatigue load limit | Pu | 49 kN |

| Reference speed | 3 200 r/min | |

| Limiting speed | 5 000 r/min | |

| Limiting value | e | 0.43 |

| Calculation factor | Y1 | 1.6 |

| Calculation factor | Y2 | 2.3 |

| Calculation factor | Y0 | 1.6 |

Tolerances and clearances

General bearing specifications

- Tolerances: Normal + CL7C, P5, total width

- Internal clearance: values

Bearing interfaces

- Seat tolerances for standard conditions

- Tolerances and resultant fit

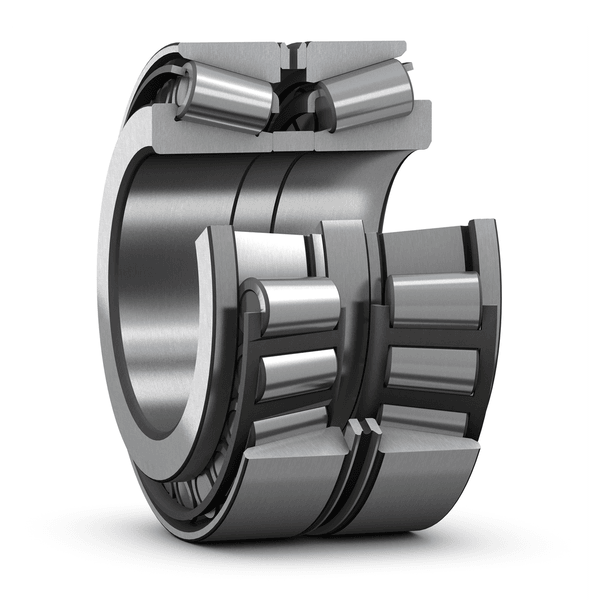

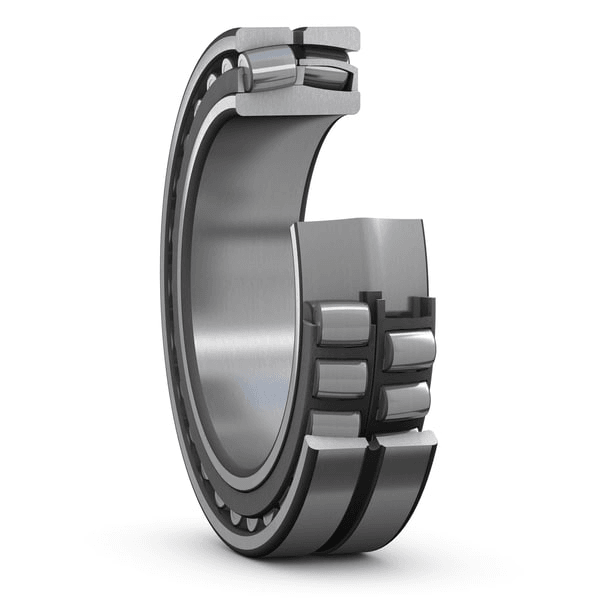

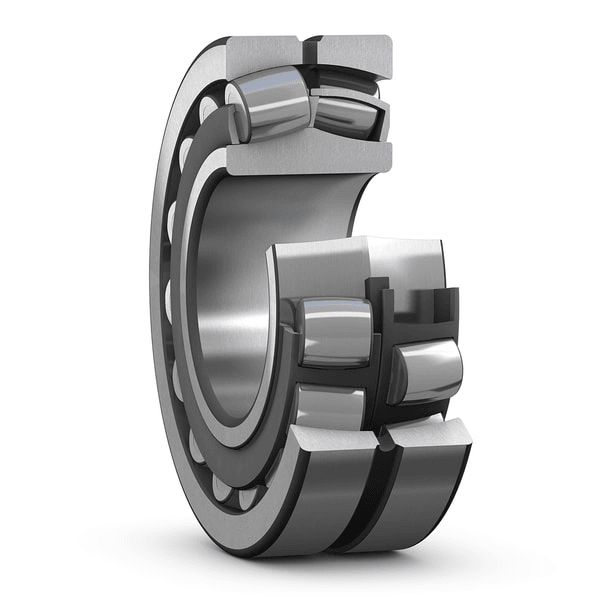

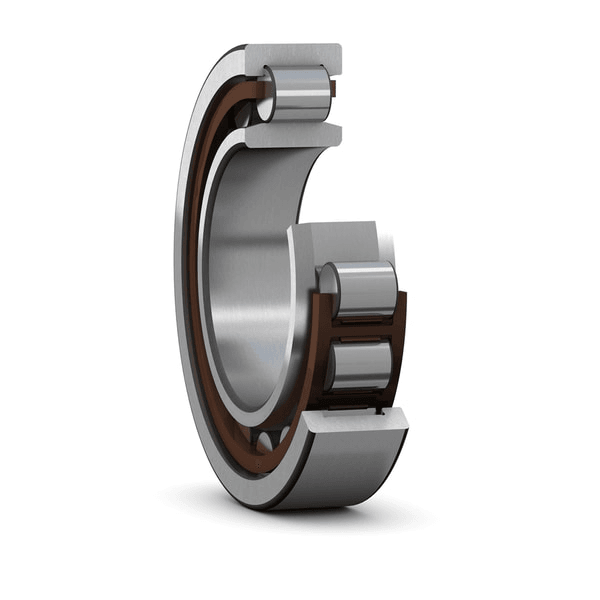

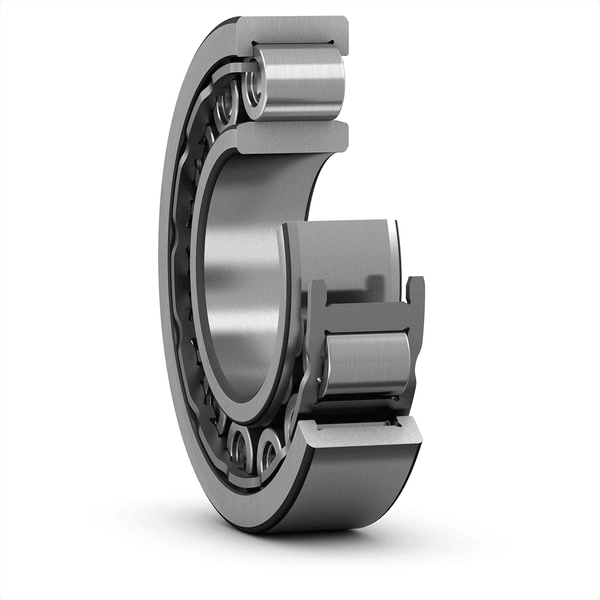

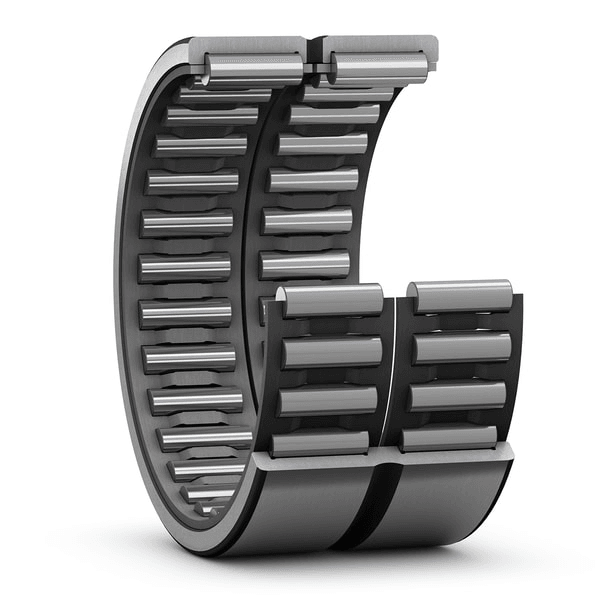

Matched tapered roller bearings arranged back-to-back (O-arrangement, load lines diverge towards the bearing axis) accommodate high radial loads, axial loads in both directions, and tilting moments. The precision manufactured intermediate rings between the innner and outer rings enable a defined internal clearance or preload to be achieved when mounted. Matched tapered roller bearings are typically used in gearboxes, hoisting equipment, rolling mills, and machines in the mining industry.

- High radial load carrying capacity

- Designed for axial loads in both directions

- Accommodate tilting moments

- Relatively high stiffness

- Surface finish on the contact surfaces of the rollers and raceways that enhances operational reliability